What’s the size of the refitting (hybridisation of Diesel/CNG) market in India for CVs?

Anshu Dewan: In India, the market is yet to realise its commercial potential and is currently at a nascent stage. As per the Transparency Market Research report, during 2021, around 975,000 vehicles inclusive of two-wheelers, three-wheelers, and four-wheelers underwent retro-fitment and the numbers are likely to increase to 2,200,000 units in 2026. The report also said that, the Indian EV Powertrain Retrofitment Market, which was worth USD 2.14 billion and is witnessing a CAGR of 13.27% for the next five years (2022-26) to reach USD 3.99 billion by 2026.

What are the key advantages of the conversion? Are the systems approved by the relevant authorities?

Anshu Dewan: Retrofitting can be a more economical option compared to purchasing new vehicles, especially for fleet operators or owners of older vehicles. It can also involve adding safety features or upgrading existing ones to enhance vehicle safety. This may include installing advanced driver assistance systems (ADAS) like lane departure warning, adaptive cruise control, or collision avoidance systems. Improved lighting, better braking systems, and structural reinforcements can also be part of safety-focused retrofitment efforts, enhancing overall vehicle safety and compliance with regulatory standards.

In 2023, IX Energy presented a retrofitted Tata LCV. How has the business picked up since then?

Anshu Dewan: We got the TA certificate in mid-December last year. Since then, we have done multiple trials. First one was with a government think-tank ISGF (India Smart Grip Foundation) in which we drove our converted electric truck from Farrukh Nagar to Chandigarh travelling almost 320 km one-way. The aim was to test the readiness of Delhi-Chandigarh freight corridors for its electrification. After that, we worked with companies like Exide Industries, DS Group, Nestle, Cremica among others. On 25 March 2024, we officially deployed our first truck to DS group – being our first traction in the market. We have targeted to deploy 24 trucks in Delhi NCR market.

How does the compulsory scrapping of commercial diesel vehicles after 15 years get impacted with retrofitting of electric systems?

MK Agrawal: Instead of scrapping entire vehicles, retrofitting enables the reuse and repurposing of existing vehicle chassis and components, minimising waste generation and landfill burden. We think the process also eliminates the need for manufacturing new vehicles, which entails carbon emissions associated with production processes, resource extraction, and transportation.

Where are the kits coming from? Are they imported or made in India?

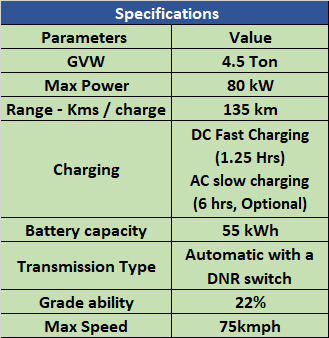

MK Agrawal: For the kit assembly most of the components are made in India like Battery pack, HVPDU, telematic devices, and other related components. Only a few components are imported like motors and controllers.

What’s your current network and business plan for the next 3-5 years?

Anshu Dewan: Our target is for the mass conversion of existing diesel vehicles. For our ESD kit, we are working with State Road Transport Corporation like Telangana and Assam for converting their buses to hybrid. Telangana SRTC will be the first one for this. For EED, we want to focus first on the Delhi NCR market and then collaborate with entrepreneurs in other areas who will work with us as certified installer of our kits.

How does the new EV policy impact your business?

Anshu Dewan: There has not been much effect as retrofitting is not incentivised like new OE vehicles.